Cooperate With Brand

Our Services

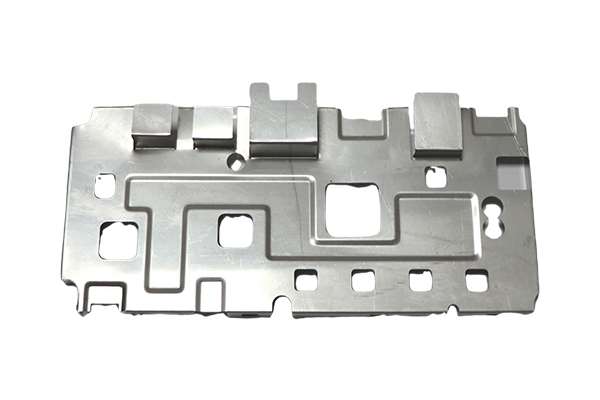

Our Outstanding Customized Parts Cases

HTSIN is a supplier of parts CNC batch processing for almost all industries. This is because our machining services can handle all possible materials and complex parts. Your required materials can include aluminum, steel, iron, bronze, zinc, their alloys, and almost any metal available. Used in electronics, communications, toys, equipment manufacturing and other fields

Our Capability

| No. | Machine | Model | Brand | Quantity | Capacity(pcs/day) | Application |

| 1 | 3,4,5 Axis CNC Machine | T500 /TC-510 | Taikan+LK | 280 | 200000 | CNC Milling |

| 2 | High-gloss CNC Machine | HXY512 | HeXinYang | 11 | 150000 | CNC Engraving |

| 3 | Polisher | XX373/XX8159 | XinRui | 4 | 100000 | Polishing |

| 4 | Centrifugal Grinder | 4049 | Xinruifeng | 4 | 100000 | Grinding |

| 5 | Nailing Tail Machine | HY318 | HuYi | 7 | 250000 | Nail Removing |

| 6 | Ultrasonic Cleaning machine | 4O48 | XinRuiFeng | 8 | 10000 | Washing |

| 7 | Sandblast Machine | 9090-ZD-6 | HuiRui | 3 | 100000 | Sand Blasting |

| 8 | Laser Engraving Machine | FM-BT-20L | BOTE | 13 | 50000 | Larser Marking |

| 9 | Automatic Lathe | 1525 | Mingyang | 20 | 300000 | Turning |

| 10 | CNC Lathe | 1525 | Mingyang | 40 | 100000 | CNC Turning |

| 11 | Automatic Cutter | HH-20D | HEHE | 2 | 10000 | Material Cutting |

| 12 | CNC Engraving and Milling Machine | S6-11 | DAYU | 50 | 20000 | Prcision CNC Cutting |

| 13 | Smart Polishing Machine | AC-WZ150A/TYPE-JD02 | RunXiangYingFeng | 9 | 10000 | Polishing |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”.

| Dimension Range (mm) | Fine (F) | Medium (M) | Coarse (C) | Very Coarse (V) +/- |

| +/- | +/- | +/- | ||

| 0.5-3 | 0.05 | 0.1 | 0.2 | — |

| 3-6 | 0.05 | 0.1 | 0.3 | 0.5 |

| 6-30 | 0.1 | 0.2 | 0.5 | 1 |

| 30-120 | 0.15 | 0.3 | 0.8 | 1.5 |

| 120-400 | 0.2 | 0.5 | 1.2 | 2.5 |

| 400-600 | 0.3 | 0.8 | 2 | 4 |

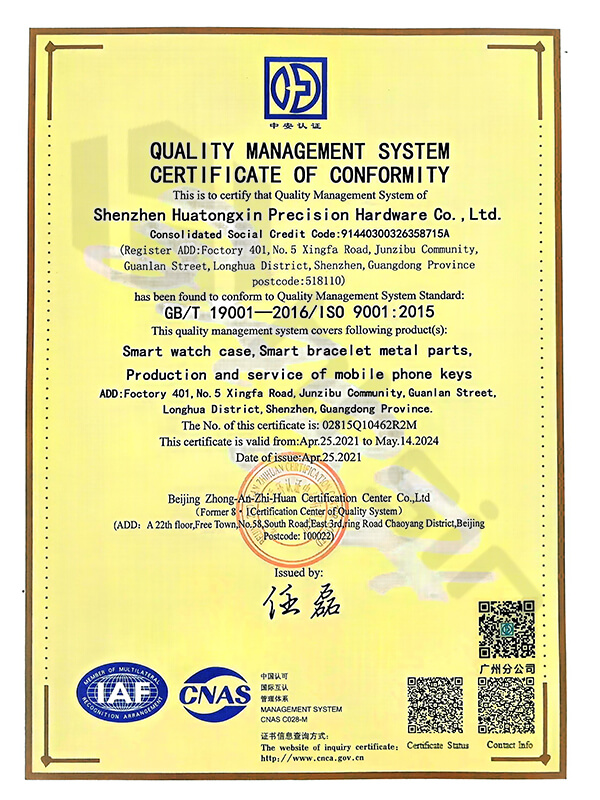

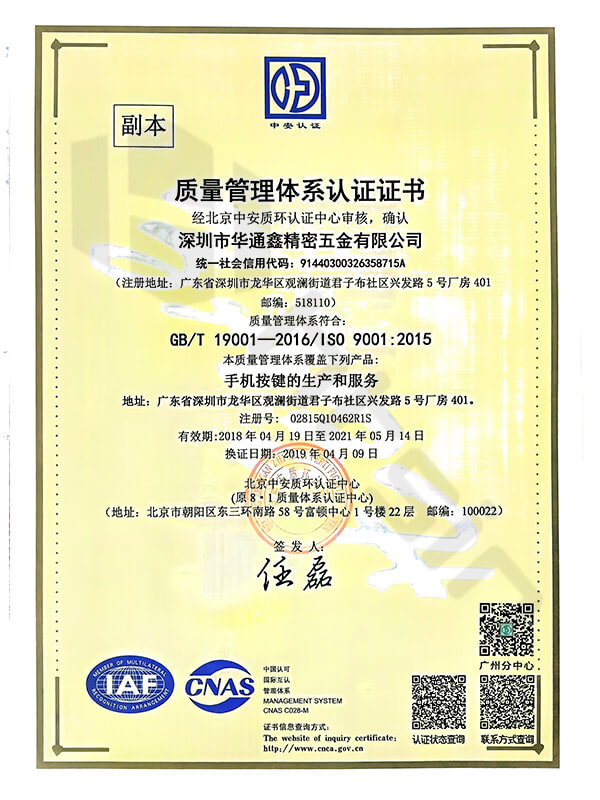

Quality Assurance

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Process control

We design multiple processes for multiple inspections, including machinist inspections and workshop QC inspections during processing

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Pre-shipment inspection report

Measure the size before delivery, fill in the side measurement data report

Highly experienced HTSIN

How to work with us ?

We strictly keep client data and information confidential, it is very easy and safe to work with us.

Our Partne

Articles from the Htsin manufacturer

Latest Htsin news

Thermal Stability in Precision Machining: Controlling Micron-Level Accuracy Under Extreme Conditions

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic