get to know us

Choose the Right Material for the Job

- Material costs can make up a significant portion of your CNC machining budget. Choosing the right material for your specific project can save you a lot of money. For example, selecting a material that is easier to machine or has lower raw material costs can significantly reduce production expenses. HTSPrecision offers a wide range of materials, from metals to plastics, ensuring that you can choose the best one that aligns with your project requirements and budget.

2. Minimize Complex Designs

While CNC machining can produce highly intricate designs, the more complex the design, the more expensive it will be to produce. To save costs, try to simplify the design without sacrificing functionality. Look for opportunities to reduce the number of tool changes or cutting operations required. HTSPrecision’s experienced engineers can help optimize your designs for manufacturability, ensuring that your parts are both high quality and cost-effective.

3. Reduce Setup Time

Setup time can be a significant factor in machining costs. Longer setup times lead to higher labor and machine costs. By designing parts that require minimal setup, you can reduce these costs. HTSPrecision utilizes advanced CNC equipment that reduces setup times, allowing for more efficient production runs and faster turnaround times.

4. Optimize Production Quantities

Many CNC machining services offer cost breaks for higher production quantities, but ordering excessive quantities can lead to waste. To find the right balance, calculate your precise needs based on demand forecasts. For small to medium runs, HTSPrecision provides flexible batch sizes, ensuring you only produce the parts you need when you need them.

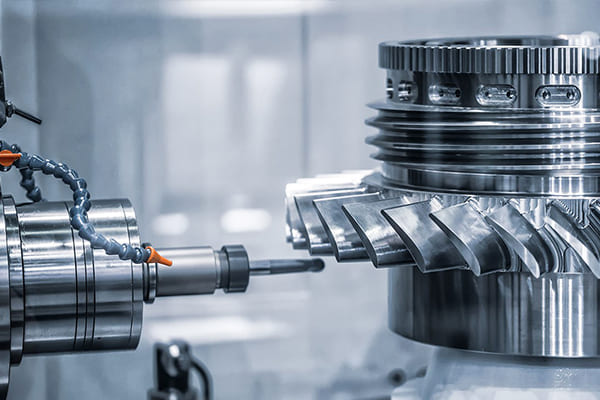

5. Use Advanced Machining Techniques

Advanced machining techniques like multi-axis CNC machining and simultaneous machining can help reduce the time and number of setups required to produce a part. These techniques allow for the completion of more complex parts in fewer steps, saving both time and money. HTSPrecision employs state-of-the-art CNC machines to offer advanced machining options that can help you achieve cost savings.

6. Implement Efficient Post-Processing

Post-processing can add significant costs to CNC machining projects. By integrating efficient post-processing techniques, you can reduce the cost of finishing parts. HTSPrecision offers integrated post-processing services, such as deburring, polishing, and coating, ensuring that your parts meet quality standards without unnecessary cost.

7. Quality Control and Inspection

Implementing proper quality control from the start of the project can help avoid costly rework or part rejection. With HTSPrecision’s rigorous inspection processes and quality assurance systems, you can ensure that every part meets the highest standards, preventing delays and extra costs due to defects or mistakes.

Conclusion

By implementing these cost-saving tips, businesses can make their CNC machining projects more efficient and cost-effective without sacrificing quality. At HTSPrecision, we specialize in providing high-precision machining solutions while helping you optimize costs. Whether you’re working on a small batch or a complex prototype, we have the expertise and equipment to meet your needs.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

We all know that processing is also a cautious work, and we must have a lot of experience in using machines and good technologies.