5 Axis CNC Machining

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

Achieve Your Goals

with Htsin Precision

For two decades, Htsin Precision has been a beacon of excellence and innovation in the realm of precision machining. Our journey, spanning 20 years, is a testament to our unwavering commitment to pushing the boundaries of what’s possible in machining. From our humble beginnings to our current status as industry leaders, we’ve consistently prioritized quality, precision, and customer satisfaction. Our foray into 5 Axis CNC machining was a natural evolution, driven by our desire to offer clients the very best in modern manufacturing solutions. When you partner with Htsin Precision, you’re not just getting a service—you’re tapping into a rich legacy of expertise, dedication, and cutting-edge technology. Every project we undertake is infused with the knowledge and experience garnered over two decades, ensuring that our clients always receive the pinnacle of what 5 Axis CNC machining can offer.

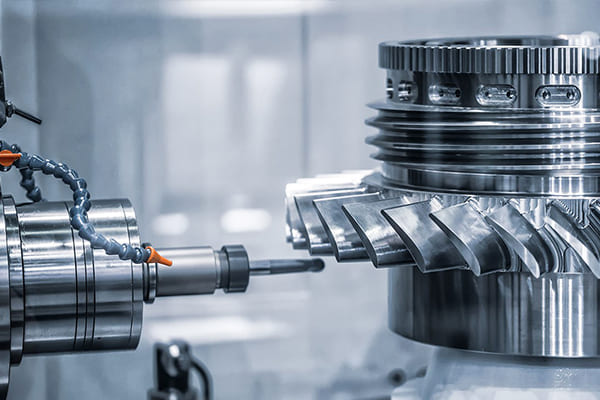

5 Axis CNC machining represents one of the zeniths in modern manufacturing innovation. Whereas traditional machining techniques might operate on three primary axes (X, Y, and Z), 5 Axis CNC machining introduces two added rotational axes. This results in a tool movement that can approach the workpiece from virtually any direction. What this means for manufacturing is profound: the ability to craft intricate parts with complex geometries, detailed contours, and nuanced precision—all in a single setup. By minimizing the need for multiple machine configurations and reducing manual repositioning, 5 Axis CNC machining not only guarantees unparalleled precision but also optimizes production timelines, making it an invaluable asset for industries where precision and efficiency are paramount.

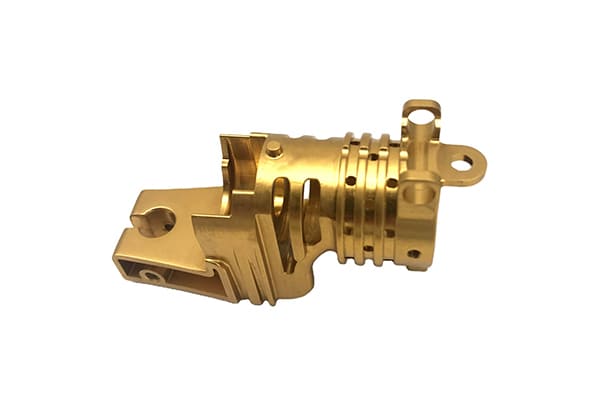

Gallery of 5 Axis CNC Machined Parts

Whether you’re a budding business or a renowned brand, we’re here to help you develop CNC-turned parts. Check our extensive library of completed parts to see what we’re capable of.

why you choose Htsin Precision

Htsin Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

Our Strengths in 5 Axis CNC Machining

- Experienced Team**: Professionals seasoned in managing and operating 5 Axis machines.

- State-of-the-Art Equipment: Housing the latest in 5 Axis CNC technology.

- Consistent Quality: Delivering impeccable results consistently across projects.

- Custom Solutions: Tailored machining solutions to meet unique project requirements.

20000+

CNC milled Projects

500+

Satisfied customers

350+

Highly qualified employees

400+

Advanced CNC Milling Machines

1st Approach We Follow

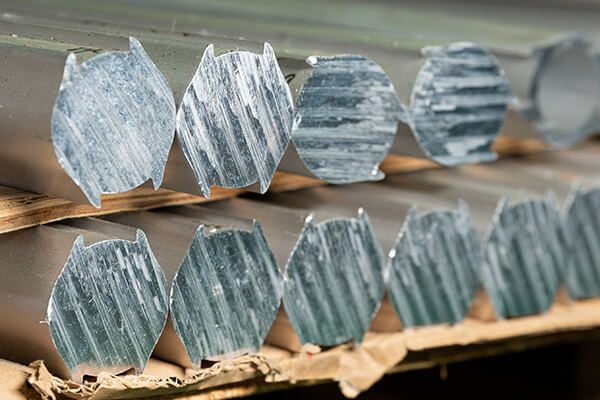

Machinable Materials in 5 Axis CNC

- Metals: Aluminum, stainless steel, titanium, brass, etc.

- Plastics: Delrin, PEEK, Polycarbonate, and more.

- Special Alloys: Detail any unique or proprietary alloys you can machine.

- Material Insights: Brief on why certain materials are preferred in specific 5 Axis applications.

2nd Approach We Follow

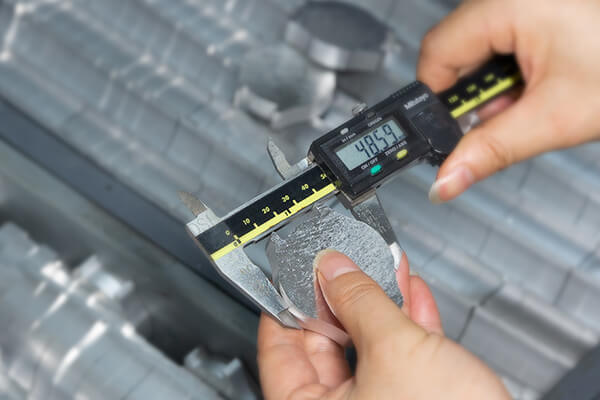

High Tolerance

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm |

| Hole diameters (not reamed) | +/- 0.025 mm |

| Shaft diameters | +/- 0.025 mm |

| Part size limit | 950 * 550 * 480 mm |

Quality Assurance

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks