CNC Machining Service

We inspire our customers & support local businesses

Free Instant Quote

24H instant price & DFM

Fast Lead-time

Parts as Fast as 3 days

Quality Assurance

ISO9001:2015 Certified

Achieve Your Goals

with Htsin Precision

Whether you need custom machined parts with complex geometries or an end-use product in the shortest possible time, Htsin Precison is precise enough to cut through all of that and realize your ideas in no time. With over 150 3, 4 and 5-axis CNC machines and over 100 different types of materials and finishes, we guarantee fast turnaround and quality for one-off prototypes and production parts.

24H

Instant Quotes

1 day

as fast as Lead time

0 pc

No MOQ

0.01mm

Max tolerance

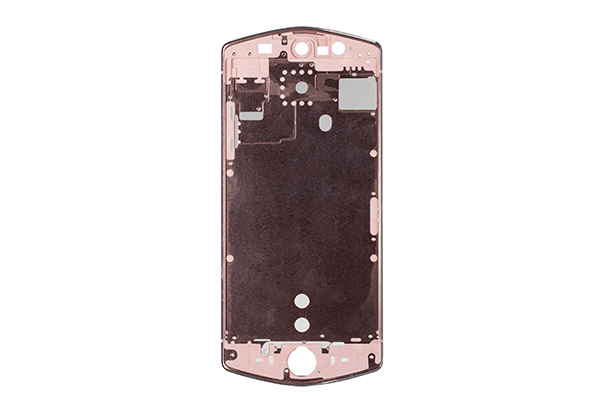

Gallery of CNC Machined Parts

Whether you’re a budding business or a renowned brand, we’re here to help you develop CNC-turned parts. Check our extensive library of completed parts to see what we’re capable of.

why you choose Htsin Precision

Htsin Precision is your premier cnc turning company for precision CNC turning services, delivering more than just quality products.

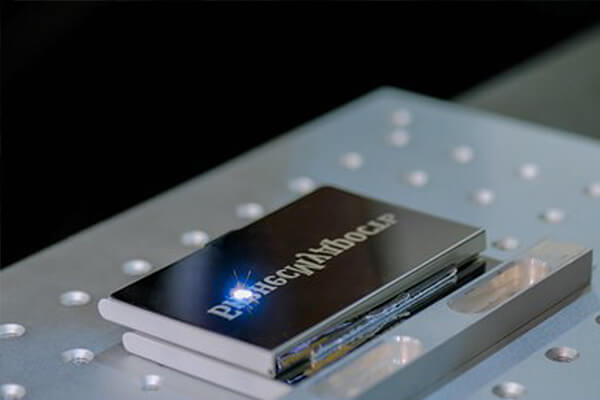

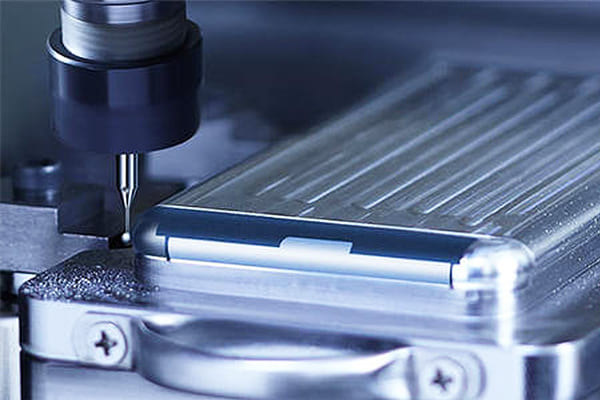

CNC Machining Workshop

Providing cost-effective and fast-paced prototyping and on-demand OEM parts manufacturing is at the heart of HTSIN PRECISION’s production philosophy. HTSIN PRECISION uses state-of-the-art CNC lathe machines to manufacture complex custom CNC turned parts from solid metals and plastics with exceptional surface finishes. From axial and radial holes to flats, grooves and slots, we can quickly manufacture these parts within 24 hours

2nd Approach We Follow

Tolerance

Our standard tolerances for custom CNC machining of metals is DIN-2768-1-m and for plastics is DIN-2768-1-c. Tolerances are greatly affected by part geometry and type of material. For case-by-case studies, please contact us with email for details.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm |

| Hole diameters (not reamed) | +/- 0.025 mm |

| Shaft diameters | +/- 0.025 mm |

| Part size limit | 950 * 550 * 480 mm |

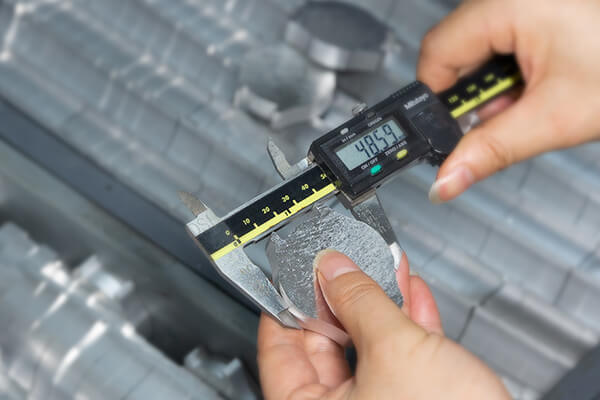

Quality Assurance

With more than 20 years of manufacturing and processing experience, we already have a complete production and processing process and quality control system, and carry out strict inspections on materials, processing, finished products, shipments and other links to ensure product quality and on-time delivery. The company has passed a number of quality management system certifications, and has been committed to providing customers with efficient and high-quality products and services.

Material inspection

We carry out quality certificate and composition analysis inspection on purchased materials

Completion inspection

Final inspection in the testing laboratory, more quality control process, until the product meets the requirements

Service first, firmly believe that product quality is the life of the enterprise, the pursuit of excellence in quality, the perfect products and services to provide customers, to win customer satisfaction.

John Deo – CEO ABCWorks