500+

Phone Parts CNC Machines

350+

Employee

professional Phone Metal Parts Maker, Supplier, Manufacturer

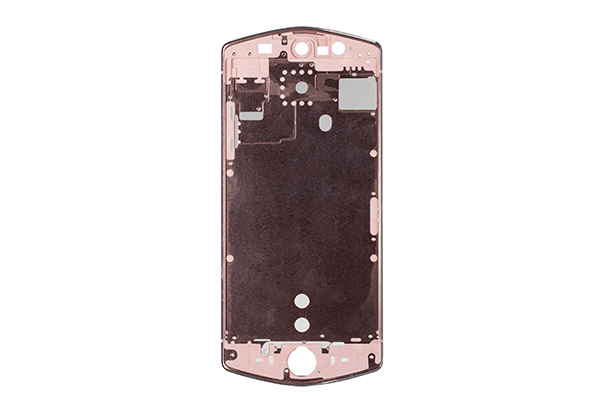

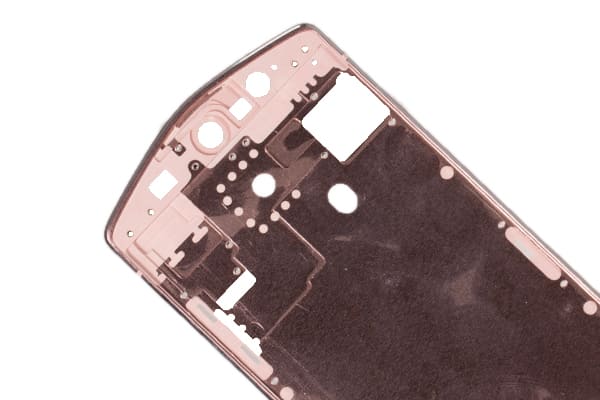

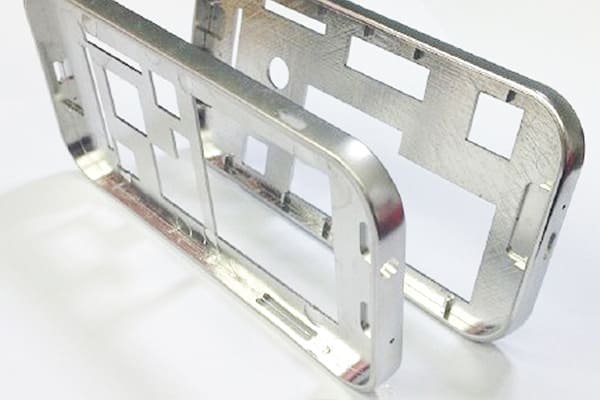

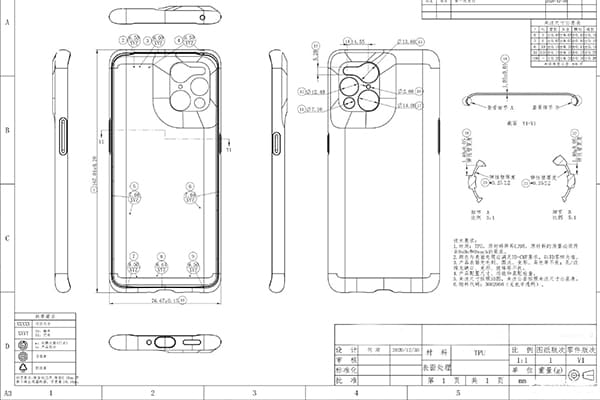

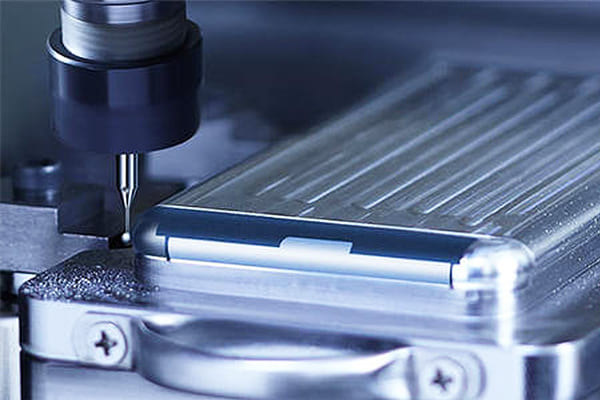

With more than 20 years of industry experience and a 5000 square meter state-of-the-art dedicated mobile phone metal parts manufacturing facility, Htsin Precision has the experience, talent and vision to provide quality OEM mobile phone parts customization and commercial mass manufacturing. Our flexible design process and extensive manufacturing scope mean we can quickly create unique designs, moving from idea to production while meeting the most demanding lead times.

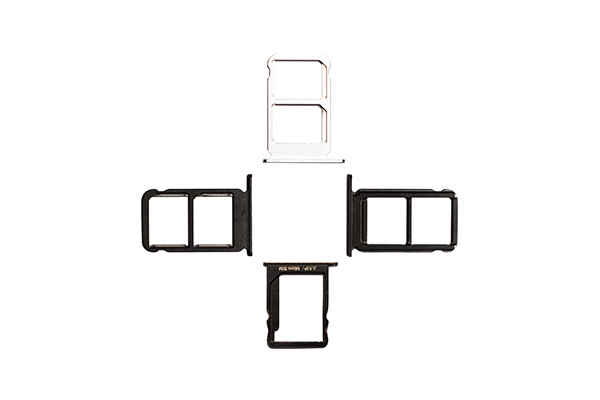

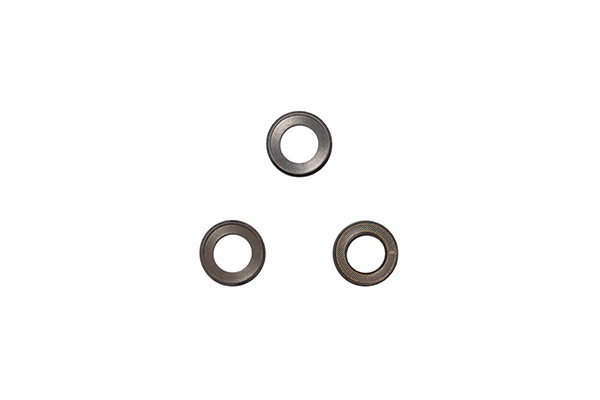

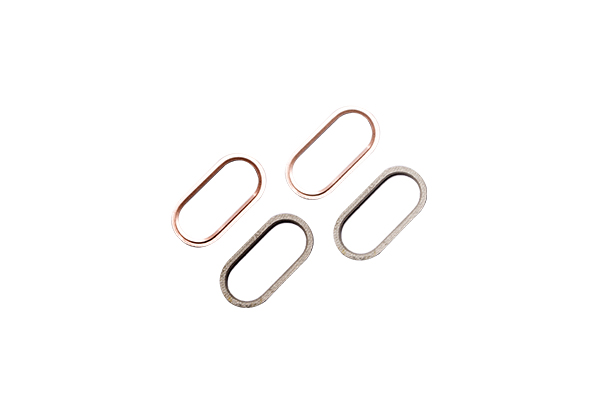

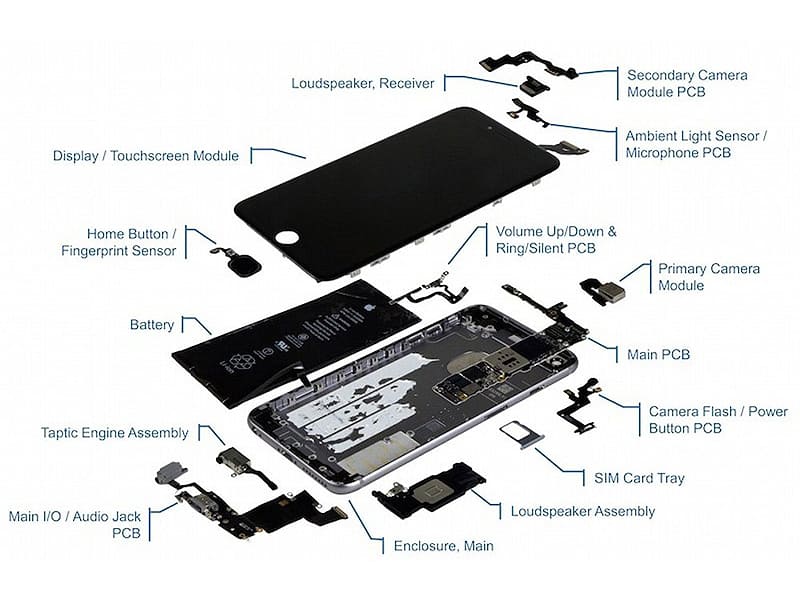

We have cooperated with Apple, Xiaomi, Huawei and other mobile phone brands for many years, and participated in the design and mass production of more than 10 kinds of smart phone parts such as mobile phone frames, buttons, SIM card trays, fingerprint rings, and camera decoration rings, with a total of more than 200,000 parts . Work with Htsin Precision to customize mobile phone metal parts according to customer design specifications (OEM). We ensure that your OEM and ODM needs are met efficiently through a well-designed process.

Brands We Work With

We are Focus on

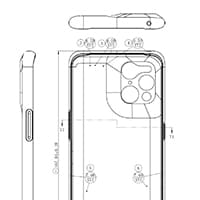

Phone Case Manufacturing

Htsin Precision is well-known as the best Phone case manufacturer, manufacturer, supplier in China.

Phone Button Manufacturing

Mass manufacture of precision mobile phone power buttons and volume buttons at a cheap price.

Why Choose Us ?

Latest Cases

HTSIN is a supplier of parts CNC batch processing for almost all industries. This is because our machining services can handle all possible materials and complex parts. Your required materials can include aluminum, steel, iron, bronze, zinc, their alloys, and almost any metal available. Used in electronics, communications, toys, equipment manufacturing and other fields

Batch and large -scale phone parts manufacturing

In the observation industry, large -scale production is a common approach. After the design and engineering stage is 1 to 2 months, we are responsible for the technical drawings, product improvement and component production in the closed supplier network in the closed supplier network, and the 3 -month component procurement stage. Then there is the assembly stage for a week. From the initial inspection to the final quality control, quality control in the entire value chain. The entire part was finally delivered to Hong Kong.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Delivery on time

Delivery is a relatively new concept in the mobile phone industry. This practice based on IT and micro -manufacturing is usually used in the automotive and electronics industry.

After 2 months of designing and sales predictions, a set of components were designed and quantified. After three months of component production in our supplier network, all mobile phone parts were purchased and placed in inventory.

Finally, our customers can use our proprietary IT solution HTSIN Precision ERP to order a design of 1 design. With the consumption of the component library, they will automatically supplement. Quality control is seamlessly integrated at each stage.

Our Capability

Our warehouse has sufficient stock of common raw materials, commonly used metal and plastic models are:

| Metal | Plastic |

| Aluminum | Acrylic |

| Brass | PTFE |

| Copper | HDPE |

| Bronze | Teflon |

| Steel | PC(Polycarbonate) |

| Stainless Steel | PVC |

| Titanium | PP(Polypropylene) |

| Zinc | ABS Plastic |

| Nylon |

Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”.

| Dimension Range (mm) | Fine (F) | Medium (M) | Coarse (C) | Very Coarse (V) +/- |

| +/- | +/- | +/- | ||

| 0.5-3 | 0.05 | 0.1 | 0.2 | — |

| 3-6 | 0.05 | 0.1 | 0.3 | 0.5 |

| 6-30 | 0.1 | 0.2 | 0.5 | 1 |

| 30-120 | 0.15 | 0.3 | 0.8 | 1.5 |

| 120-400 | 0.2 | 0.5 | 1.2 | 2.5 |

| 400-600 | 0.3 | 0.8 | 2 | 4 |

At Htsin Precision, we believe that the difference between a beautiful watch and a great watch is the attention to detail, the finishing of the parts and most importantly the case. We offer different watch finishes to give your creations the shine it deserves.

As well as our extremely precise polishing methods that produce sparkling results, we also offer ultra-fine shot peening, chemical etching, stamping and PVD to make every detail sparkle.

We can do surface treatment according to customer needs, the processing methods are as follows:

- Anodized

- Polishing

- Nickel plating

- Zinc plating

- Brushing

- Laser engraving

- Oxide black

- Heat treatment

- Sandblasting

- Electrophoresis etc.

client

testimonials

Very High quality, on time delivery and professional services. Highly Recommended 👍

Edward Kinsjer

It All Starts With a consultation!

Watch Parts Manufacturing on Demand

For any kind of quiries, Please Email

No. 5, Xingfa Road, Junzibu Community, Guanlan Town, Longhua District, Shenzhen, China 518100