get to know us

Custom Machining Services Explained

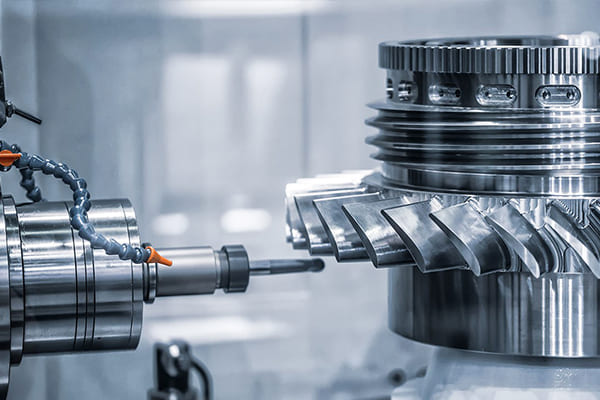

Custom machining refers to the process of manufacturing metal or plastic parts based on customer-provided drawings, models, or technical specifications. It’s widely applied in industries such as automation, medical equipment, automotive, aerospace, and electronics.

We offer:

CNC milling and turning

EDM (Electrical Discharge Machining)

Sheet metal fabrication

Surface finishing

Whether you need a single prototype or a low-volume production run, our facility adapts to your specific needs.

Why Choose Our Custom Machining Services?

✅ High Precision:

Our advanced CNC equipment ensures tolerance levels as tight as ±0.0004 inches (±0.01mm), meeting the strictest technical requirements.

✅ Flexible MOQ:

We support small batches, starting from just 1 piece—ideal for startups and prototyping projects.

✅ Fast Prototyping:

We offer expedited prototyping services with delivery in as fast as 24 hours, helping speed up your development cycle.

✅ One-Stop Service:

From drawing assistance, material sourcing, machining, to quality control—everything is managed in-house.

✅ Traceable Quality Assurance:

Every order is logged, photographed, and inspected before shipment, with records maintained for future repeatability.

🛠️ Our Machining Process: Step by Step

-

Requirement Review – Our engineers assess your drawings or samples and confirm technical requirements.

-

Quotation & DFM Feedback – We provide a quote and, if needed, design-for-manufacturing suggestions.

-

Material Preparation – We source certified raw materials based on the specifications.

-

CNC Machining – The parts are machined using CNC milling or turning, with precision control throughout.

-

Surface Treatment – Options include anodizing, powder coating, polishing, bead blasting, etc.

-

Inspection & Shipping – Dimensional reports and quality control checklists are conducted before packaging.

🧪 Equipment & Capabilities

-

3-axis, 4-axis, and 5-axis CNC machining centers

-

Precision turning lathes

-

EDM and wire cutting

-

Coordinate Measuring Machine (CMM)

-

Laser engraving and part numbering systems

-

ISO 9001 certified quality processes

Frequently Asked Questions (FAQ)

Q: Can you produce without a drawing?

Yes! We offer drawing and modeling services if you provide a sample or basic specifications.

Q: What materials do you support?

We work with aluminum, stainless steel, brass, copper, POM, ABS, PC, and more.

Q: Which payment methods do you accept?

We accept PayPal, credit cards, bank transfers, and other international payment methods.

Q: Is rush service available?

Absolutely. We provide 24–72 hour rapid prototyping options depending on complexity.

Ready to Start Your Custom Machining Project?

Upload your drawings or contact our team to get a free quote within 1 hour.

We’re here to bring your designs to life—quickly, precisely, and reliably.

continue reading

Related Posts

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

According to product design, once you decide to use CNC to process the product, you should choose the best material, whether it is metal, plastic

We all know that processing is also a cautious work, and we must have a lot of experience in using machines and good technologies.